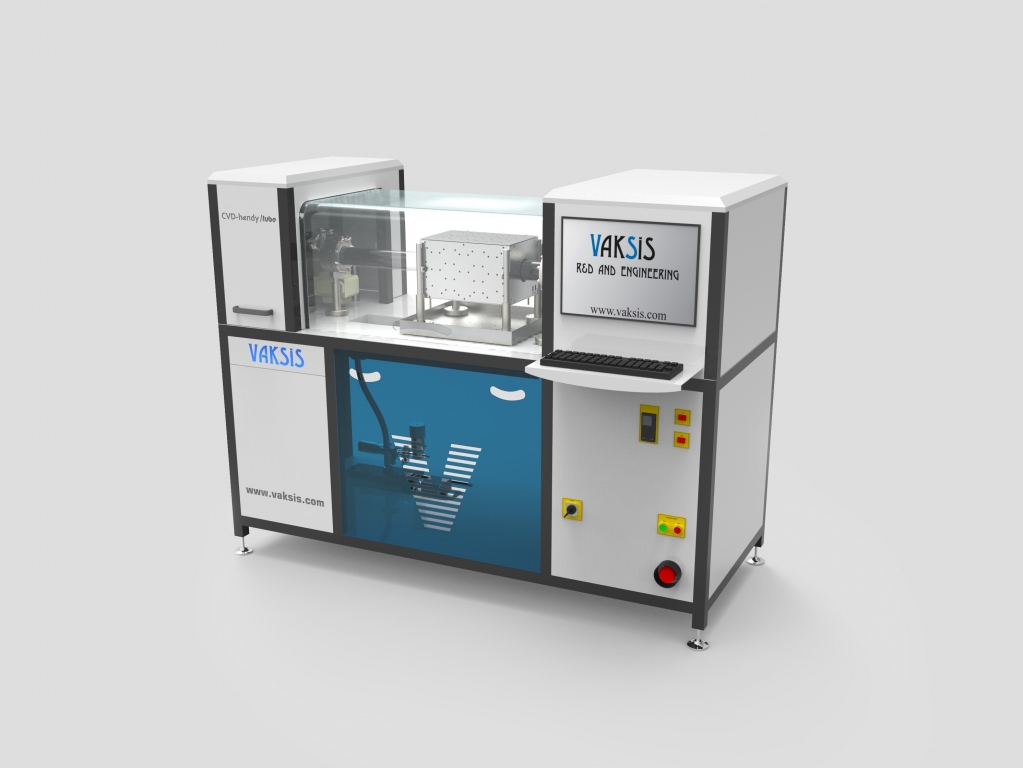

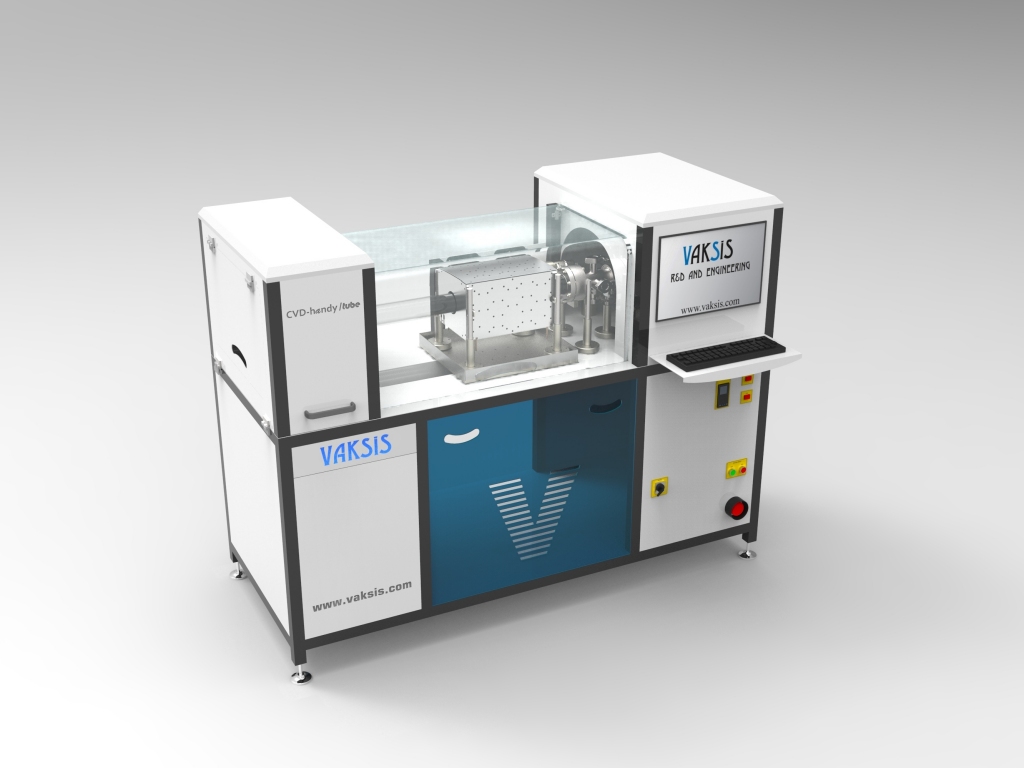

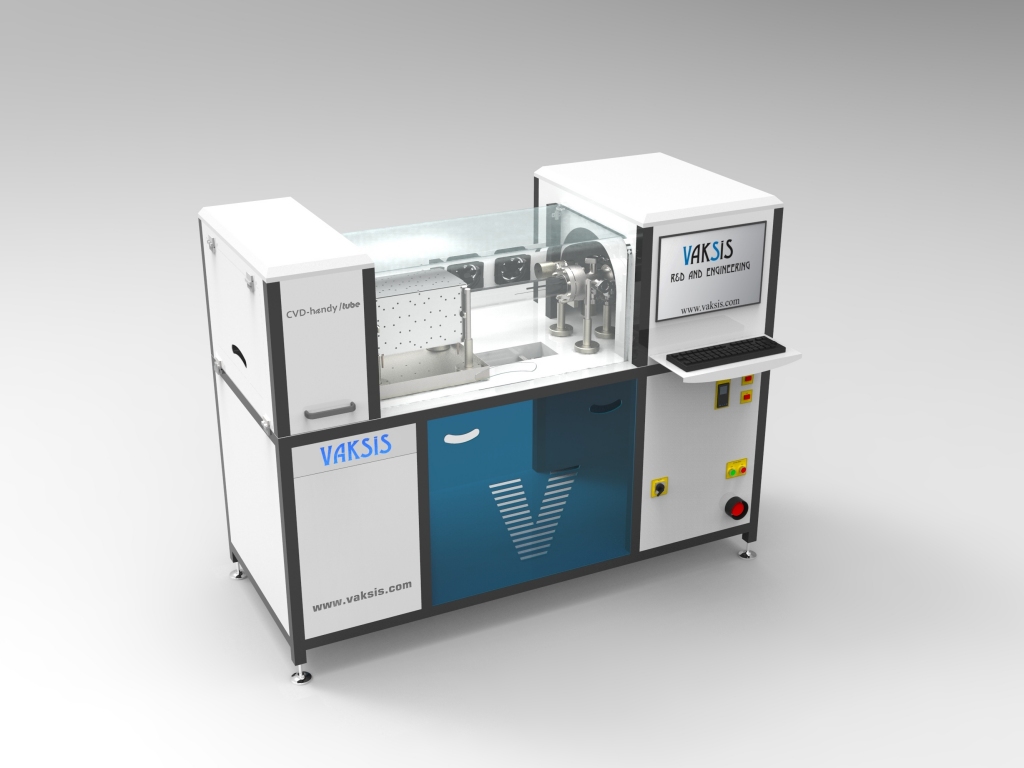

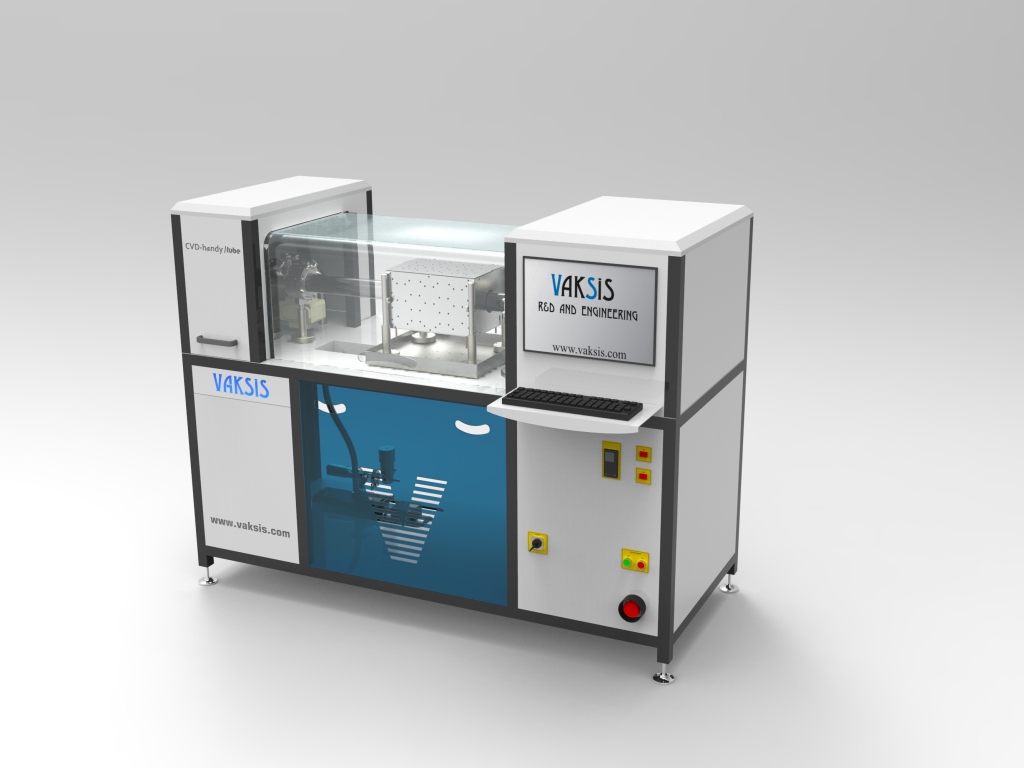

CVD Handy Tube

Low Pressure Chemical Vapor Deposition System (LPCVD) is similar to other types of CVD where gaseous species reacts on a solid surface or wafer. The LPCVD process has a quartz tube co-axially placed in tube furnace. The main advantages of LPCVD are the excellent uniformity of thickness and purity, simple handling, homogeneity of deposited layers and high reproducibility.

This “CVD-handy tube” series is a high temperature CVD system, most successfully applied in deposition of graphene, carbon nanotubes and nanowires (ZnO, GeO).

- Ultimate Vacuum Pressure ≈ 10-6 Torr

- Quartz Tube Diameter max. 130 mm

- Max. Temperature 1100oC

- Continuous Working Temperature 1050oC

- Heating Area Length 250 mm

- Temperature Control System PID method

- Cooling Rapid cooling with lifting mechanism

- Loading From one end of the quartz tube

- Control Fully Automatic (Semi-Automatic is Optional)

- Number of MFC’s for different Gas Types Max 12

If requested, our CVD-handy tube systems can be combined with Inductively Coupled Plasma (ICP).